Imagine entering a factory where machines communicate with each other, production lines set themselves up automatically, and managers receive immediate feedback on every process, from raw materials to delivery to the customer.

That's no longer a vision of the future.

This is what Microsoft Dynamics 365 for Manufacturing makes possible today.

We are in the midst of a monumental shift in manufacturing. The Industry 4.0 revolution is upon us. Smart technology, IoT (Internet of Things), and AI are changing how we design, manufacture, and deliver products.

Manufacturing is no longer about producing things; it is about infusing intelligence into everything we produce.

And if you're a manufacturer trying to remain competitive, you know all too well how these changes are happening at lightning speed.

Supply chains are unpredictable. Customer demand continues to change. Margins are slimmer than ever.

That is why digital transformation is in fact no longer an option -- it is a necessity.

An Overview of Microsoft Dynamics 365 and Its Manufacturing Capabilities

At its core, Dynamics 365 is a powerful suite of business applications developed by Microsoft to unify data, streamline workflows, and simplify complex operations. But when it comes to manufacturing, it takes things to another level.

Here’s why:

Dynamics 365 brings real-time visibility into your production process, helping you track raw materials, monitor machine performance, and manage orders without missing a beat.

It uses built-in AI and analytics to forecast demand, minimize downtime, and optimize inventory, so you can produce smarter, not harder.

From planning and scheduling to delivery and post-sale support, everything happens in one place. That means less confusion, faster decisions, and greater profitability.

And when you undergo a Microsoft Dynamics 365 implementation, you’re not just installing software; you’re reshaping how your entire organization operates.

You’re creating a connected, data-driven environment where departments collaborate effortlessly, and insights flow in real time.

How Microsoft Dynamics 365 is Changing the Manufacturing Industry?

If you’ve been in manufacturing long enough, you know the industry is no stranger to change, but the pace of innovation today is like never before.

And right at the heart of this digital revolution is Microsoft Dynamics 365 for the manufacturing industry.

Let’s look at how this platform is completely reshaping the way manufacturers plan, produce, and deliver value, smarter and faster than ever before

1. Real-Time Visibility Across Operations

Ever felt like you’re running your factory half-blind? With Microsoft Dynamics 365 for Manufacturing Solution, you don’t have to guess what’s happening on the floor anymore.

You get real-time visibility into production schedules, equipment status, and inventory, all from one unified dashboard.

That means fewer delays, faster responses, and smarter decisions.

2. Predictive Maintenance with IoT and AI

Downtime can drain profits faster than anything else.

But with Dynamics 365 in Manufacturing, predictive maintenance powered by Azure IoT and AI changes the game.

Instead of reacting to breakdowns, you can predict them before they happen.

The system monitors machine health, detects patterns, and alerts your team early — keeping production steady and maintenance costs low.

3. Streamlined Supply Chain Collaboration

Your supply chain is the backbone of your business, and Dynamics 365 strengthens it like never before.

It connects suppliers, distributors, and partners in real time so everyone stays in sync.

From tracking raw materials to ensuring timely deliveries, Microsoft Dynamics 365 for the manufacturing industry keeps your operations transparent and collaborative.

4. Smarter Planning and Forecasting

Manufacturing isn’t just about production — it’s about planning the right things at the right time.

Dynamics 365 combines Power BI analytics with AI-driven forecasting to help you anticipate demand and manage resources efficiently.

No more overproduction, understocking, or guesswork — just data-driven clarity that saves both time and money.

5. Enhanced Customer Engagement

Your customers expect faster deliveries and higher quality, and Dynamics 365 helps you deliver both.

Through connected CRM and ERP systems, your teams can access order histories, service data, and customer feedback instantly.

That means every customer interaction is personalized, informed, and timely, boosting satisfaction and long-term loyalty.

6. Empowered Workforce and Productivity

Empower your people with technology that actually works for them.

Dynamics 365 integrates with Microsoft Teams, Power Apps, and Copilot AI, giving your employees tools to automate tasks, collaborate easily, and make smarter decisions on the go.

In short, your workforce becomes more connected, efficient, and capable than ever before.

7. Sustainability and Cost Efficiency

Sustainability isn’t just good ethics, it’s good business.

With advanced analytics and process automation, Microsoft Dynamics 365 for Manufacturing Solution helps you minimize waste, cut energy costs, and improve efficiency across production lines.

You can measure, manage, and optimize every resource, creating a smarter, greener, and more profitable future.

Key Features that Revolutionize Manufacturing Operations

If you’re ready to bring speed, accuracy, and innovation to your factory floor, Microsoft Dynamics 365 Manufacturing has everything you need.

It’s not just another ERP system; it’s your partner in building smarter, more connected production environments that deliver results from day one.

Here are the standout features that are transforming manufacturing operations worldwide:

1] Unified Production Management

No more juggling spreadsheets or multiple apps. Dynamics 365 brings every part of your production together from planning and scheduling to resource allocation into one platform.

You can easily monitor progress, identify bottlenecks, and make adjustments in real time.

2] Predictive Quality Control

Forget reactive inspections. With built-in AI and data analytics, you can predict quality issues before they affect your output.

This feature ensures consistent product standards, reduces rework, and improves overall efficiency, making your customers happier and your processes leaner.

3] Advanced Inventory & Warehouse Management

Stay in control of your stock with real-time visibility into every unit — raw materials to finished goods.

Microsoft Dynamics 365 Manufacturing helps you reduce inventory costs, avoid overstocking, and make smart restocking decisions automatically through demand forecasting.

4] IoT-Driven Equipment Insights

Your machines can tell you more than you think. By connecting IoT sensors with Dynamics 365, you can track performance, detect anomalies, and schedule maintenance automatically.

This prevents unplanned downtime and keeps your production running like a well-oiled machine.

5] Smart Supply Chain Integration

Managing multiple suppliers can get messy, but not with Dynamics 365. The system connects your entire supply chain in real time, from procurement to delivery.

That means fewer surprises, faster responses, and smoother coordination across every stage.

6] AI-Powered Demand Forecasting

Guesswork has no place in modern manufacturing. With AI-powered insights, Dynamics 365 predicts future demand using real-time market data and sales patterns.

This helps you plan production more accurately, reduce waste, and meet customer needs right on time.

7] End-to-End Financial Visibility

Profitability starts with transparency. Dynamics 365 provides detailed financial insights into production costs, supplier spending, and overall ROI.

You can track margins, identify inefficiencies, and make data-driven financial decisions that improve performance across your business.

8] Seamless Collaboration with Microsoft Tools

Dynamics 365 connects effortlessly with Teams, Power BI, and Azure, giving your teams one place to communicate, analyze, and act. Whether you’re on the shop floor or in the office, everyone stays aligned and productive.

With all these powerful features driving efficiency and innovation, it’s clear how Microsoft Dynamics 365 Manufacturing transforms day-to-day operations.

But what about the bigger picture, the real challenges manufacturers face every day?

Let’s explore some of the challenges that Dynamics 365 solves head-on.

Industry Challenges That Microsoft Dynamics 365 Solves

Manufacturing today comes with its fair share of hurdles, from disconnected systems to unpredictable supply chains. That’s where Microsoft Dynamics 365 for Manufacturing steps in to simplify, automate, and empower your operations.

Here are some common challenges and how this solution helps you tackle them:

Challenge 1: Disconnected Operations

Siloed systems lead to poor coordination and low visibility.

Solution: Msoft Dynamics 365 Manufacturing connects all departments in one unified platform, ensuring seamless data flow, better communication, and faster decision-making.

Challenge 2: Supply Chain Disruptions

Unpredictable logistics and shortages cause costly production delays.

Solution: With real-time insights, you can anticipate supply issues early, adjust plans quickly, and maintain smooth, uninterrupted manufacturing cycles.

Challenge 3: Rising Production Costs

Unmonitored resource usage drives up operational expenses.

Solution: Smart analytics help you detect inefficiencies, optimize resources, and reduce overall manufacturing costs effectively.

Challenge 4: Limited Data Visibility

Lack of actionable insights hinders strategic planning.

Solution: The platform provides real-time data visualization and analytics, empowering you to make informed, data-driven business decisions instantly.

Challenge 5: Workforce Skill Gaps

Employees often struggle with complex systems and outdated tools.

Solution: User-friendly dashboards and guided automation make it easier for teams to adapt quickly and stay productive with minimal training.

Challenge 6: Measuring ROI Effectively

Leaders hesitate to invest without knowing the returns.

Solution: The cost is quickly justified through automation, reduced downtime, and measurable operational efficiency gains.

While we have challenges covered. Now, it’s time to talk about business benefits.

Business Benefits of Implementing Dynamics 365 in Manufacturing

By utilizing a Dynamics 365-based manufacturing solution, you are automating processes, but also creating a more intelligent and nimble organization.

Here are the benefits of the actual and measurable value generated by the solution, from cost efficiency to collaboration and actual decision-making capabilities, in your manufacturing ecosystem.

1. Productivity and On-Time Deliveries

Dynamics 365 Manufacturing enhances workflow efficiency by connecting machines, people, and information, enabling you to track operations in real-time and forecast delays before they impact your schedule, and automate related scheduling to ensure timely delivery.

2. Operational Efficiency and Scalability

Utilizing Dynamics 365 in manufacturing allows you to automate steps and processes based on repeated tasks, reducing unnecessary waste while maximizing visibility into your resource consumption.

Microsoft Dynamics 365 can grow with your business and allow you to easily scale your operations while being most efficient in doing so, without adding cost to your operation. You will be able to increase capacity once market demand grows.

3. Collaboration Between Departments

Dynamics 365 in Manufacturing enables you to reduce or eliminate silo based internal organization of business processes into floppy management.

Teams, planning, production, inventory, logistics, and other departments are tied together with real-time data and information.

Therefore, providing you with clear communications, instant approvals, and collaboration between parties not seen in a siloed internal organization.

The increased interaction and collaboration between parties creates team cohesiveness and, therefore, an added productive emphasis.

4. Improved Decision Making

Decisions can generate significant value to product quality, circumvent operational frustration, and create a better safety environment, based on reporting and analytical tracking based on habits.

AI and Algorithms in reporting and analytical datasets display the value of every team member's contribution to the overall operation and success of a manufacturing business.

Find out the real-world use cases.

Real-World Success Stories: Dynamics 365 Manufacturing in Action

When it comes to digital transformation, seeing real-world examples always hits differently. It’s one thing to talk about efficiency and automation, but it’s another to see how Dynamics 365 Manufacturing is helping actual companies redefine their processes, improve output, and thrive in a competitive global market.

Let’s look at some inspiring success stories that show how businesses turned challenges into growth with Dynamics 365.

Case Study 1: Automotive Manufacturer Achieving Predictive Production

An automotive manufacturer used Microsoft Dynamics 365 for Manufacturing with AI and IoT insights to predict equipment failures early. This proactive approach reduced downtime by 30%, improved scheduling accuracy, and optimized production efficiency across multiple assembly lines.

Case Study 2: Electronics Firm Reducing Downtime with IoT Data

An electronics company integrated Dynamics 365 in Manufacturing with IoT sensors to track real-time machine performance. The result: 25% less downtime, improved maintenance scheduling, and a 15% reduction in energy consumption across all production facilities.

Case Study 3: Food Processing Company Enhancing Compliance and Traceability

A food manufacturer adopted Microsoft Dynamics 365 for Manufacturing to boost traceability and regulatory compliance. Automated quality checks and batch tracking helped reduce manual errors by 40% and accelerated audit responses significantly.

Case Study 4: Textile Manufacturer Boosting Efficiency with Real-Time Analytics

A leading textile manufacturer implemented Dynamics 365 Manufacturing to gain real-time visibility into production and quality control. With automated data capture and Power BI dashboards, they identified inefficiencies early, reduced fabric waste by 18%, and improved order fulfillment speed. The result, faster delivery cycles and higher customer satisfaction.

Case Study 5: Heavy Equipment Producer Streamlining Supply Chain Operations

A global heavy machinery producer used Microsoft Dynamics 365 for Manufacturing to unify procurement, inventory, and logistics under one platform. By integrating predictive analytics and AI-driven insights, they optimized component sourcing, minimized stock shortages, and cut supply chain costs by 22%, ensuring smoother operations across their international plants.

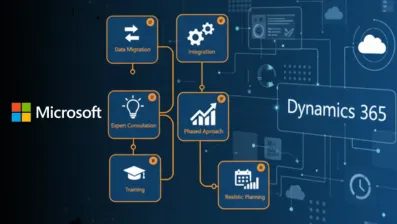

How to Implement Dynamics 365 in Manufacturing?

Implementing D365 in Manufacturing isn’t just a tech upgrade; it’s a business transformation. The process helps you align your people, processes, and data on one intelligent platform to drive efficiency and scalability. But to get the most out of your investment, you need a clear roadmap.

Here’s a step-by-step process to ensure a smooth implementation of Dynamics 365 in manufacturing that delivers real business impact.

Step 1: Assess Your Current Operations

Start by taking a close look at your existing manufacturing ecosystem — from your production lines to your supply chain and finance systems.

Identify inefficiencies, gaps, and areas where automation can create the most value. This assessment gives you a baseline for improvement and helps you prioritize what matters most.

Once you understand where you stand, you can map out how D365 in Manufacturing will enhance your operations.

Step 2: Define Business Objectives

Before diving into configurations and integrations, define what success looks like for your organization.

Are you aiming to reduce downtime, improve forecasting accuracy, or enhance customer delivery timelines? Setting specific, measurable goals ensures every part of your Dynamics 365 implementation aligns with a clear outcome.

These objectives will guide your team, prevent scope creep, and ensure the project stays focused on value creation rather than just deployment.

Step 3: Choose the Right Modules

Every manufacturer is different, and that’s the beauty of Dynamics 365.

You can integrate Microsoft Dynamics 365 for manufacturing by selecting only the modules that perfectly align with your operations, like Microsoft Dynamics 365 modules for Supply Chain Management, Finance, Production Planning, and Sales.

Each module is designed to solve specific challenges, whether it’s optimizing inventory, automating procurement, or enhancing quality control.

Choosing the right components ensures that your team uses tools built specifically for your workflow instead of unnecessary add-ons that slow performance.

Step 4: Data Migration and Integration

Clean, reliable data is the backbone of a successful system.

Before implementing Dynamics 365, evaluate your existing data sources and eliminate duplicates or outdated information.

Integrate your old systems with the new platform to maintain business continuity and data consistency.

A smooth migration process ensures that when you go live, your entire manufacturing operation, from procurement to delivery, runs seamlessly without missing a beat.

Step 5: Train and Empower Your Team

Even the most advanced technology is only as good as the people using it.

Conduct hands-on training sessions to help your team understand the new workflows, dashboards, and analytics tools.

Encourage user feedback and address pain points early. When employees feel confident with the system, adoption becomes smoother, and productivity increases almost immediately.

Step 6: Test, Monitor, and Optimize

Once implementation is complete, continuously monitor system performance.

Use built-in analytics to track KPIs, identify inefficiencies, and uncover new opportunities for automation.

Dynamics 365 evolves with your business, so regular optimization ensures you’re always leveraging the platform’s latest features for maximum ROI.

So, this is a proper process to integrate Dynamics 365 in manufacturing services. Let’s find out how to measure success.

How to Measure Success After Implementation?

Once you’ve completed the Microsoft Dynamics 365 for Manufacturing Implementation Process, it’s important to track how well it’s driving transformation.

Measuring success goes beyond installation; it’s about assessing performance, productivity, and profitability improvements across your manufacturing ecosystem.

Let’s get to know:

1. Production Efficiency Gains

Start by evaluating your production timelines and workflow accuracy. Are products moving through the line faster? Are there fewer bottlenecks or rework instances?

When your Dynamics 365 in Manufacturing system streamlines processes, automates repetitive tasks, and reduces downtime, you’ll notice smoother operations, faster deliveries, and a significant improvement in production output.

2. Cost Reductions

One of the biggest indicators of success is cost optimization.

Compare pre- and post-implementation expenses from raw materials to maintenance and labor.

If you’re seeing reduced waste, better inventory control, and minimized operational overhead, your Dynamics 365 solution is effectively improving profitability while maintaining product quality and process stability.

3. Improved Data Visibility

With Microsoft Dynamics 365 for Manufacturing, one of the strongest advantages is enhanced visibility.

Success can be measured by how easily teams access real-time data for better decision-making.

If managers can track performance, forecast demand, and resolve production issues proactively, your implementation is clearly improving transparency and operational intelligence.

4. Employee and Partner Productivity

Gauge how effectively employees, suppliers, and partners adapt to new workflows. Increased user adoption, quicker collaboration, and smoother communication signal success.

When people spend less time on manual data entry and more time innovating, your implementation is empowering teams to focus on higher-value tasks that drive the business forward.

5. Business Growth and ROI

Ultimately, measure how the system impacts your overall business performance. Increased throughput, faster order fulfillment, and better customer satisfaction are strong ROI indicators. When your implementation helps you scale operations, make smarter investments, and stay competitive in a fast-changing market, it proves that your digital transformation is truly delivering long-term value.

Let’s dive in to know the cost.

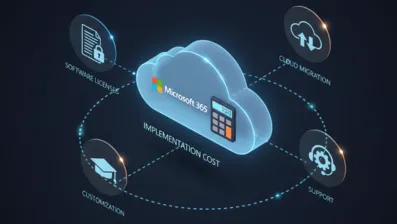

How Much Does it Cost to Implement Microsoft Dynamics 365 for Manufacturing?

When implementing Microsoft Dynamics 365 for your manufacturing company, the Microsoft Dynamics 365 Implementation Cost will be influenced by several factors.

Such as the number of users, modules selected, level of customization to the system, and deployment type (either cloud or on-premises).

Smaller manufacturers may start with core modules, while larger multi-site companies tend to opt for more robust integrations, thereby increasing their overall costs.

Here’s a simplified guide of what you can expect:

Component | Estimated Cost Range (USD) | Description |

Licensing | $50 – $210 per user/month | Depends on selected modules and user roles |

Implementation | $20,000 – $150,000 | Covers setup, data migration, and customization |

Training | $2,000 – $10,000 | Employee onboarding and knowledge transfer |

Support & Maintenance | $5,000 – $25,000 annually | Includes updates, monitoring, and issue resolution |

How DotStark Can Help You Implement Dynamics 365 in Manufacturing?

Transforming your manufacturing operations isn’t just about deploying new software; it’s about making your processes smarter, faster, and more connected.

That’s where DotStark steps in. As experts in Microsoft Dynamics 365 Consulting services, we help you design, implement, and optimize solutions that perfectly align with your manufacturing goals.

From module selection and integration to employee training and post-launch support, our team ensures a seamless transition with minimal disruption.

Whether you’re looking to automate production workflows, gain real-time insights, or improve supply chain efficiency, DotStark delivers customized strategies that make your digital transformation truly worthwhile.

Conclusion

Microsoft Dynamics 365 is redefining how manufacturers operate, driving agility, efficiency, and smarter decision-making.

But implementing it the right way requires more than just technical know-how; it needs a trusted partner who understands both technology and industry challenges.

DotStark empowers manufacturers to get the most out of their Dynamics investment through tailored solutions and end-to-end guidance.

If you’re ready to modernize your manufacturing ecosystem, now’s the time to leverage Dynamics 365 with DotStark by your side.

Frequently Asked Questions

Dynamics 365 helps manufacturers streamline production, manage inventory, optimize supply chains, and improve collaboration across departments through real-time insights and automation.

Implementation time varies from a few weeks to several months, depending on the complexity, number of modules, and data migration requirements.

Yes, Dynamics 365 offers scalable modules that can be tailored to fit the needs and budgets of both SMBs and large enterprises.

DotStark focuses on customized solutions, deep industry expertise, and continuous post-implementation support, ensuring long-term business value.

You can start by identifying your required modules, number of users, and desired integrations. DotStark offers consultation to provide an accurate cost estimate based on your needs. Overall, the cost of implementation can be around $20,000 to $150,000+.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

+91 9680599916

+91 9680599916

vanshika@dotstark.com

vanshika@dotstark.com